Chip manufacturing, Musk is "serious," 2026

Musk accelerates the advancement of the chip localization strategy, planning to establish a complete chip industry chain in the United States and gradually reduce dependence on external supply chains. The PCB center in Texas is already operational, and the equipment installation for the FOPLP factory is underway, with small-scale mass production expected in the third quarter of 2026. SpaceX is promoting the integration of satellite chip packaging processes to reduce costs. Musk plans to build a wafer factory with a target capacity of one million wafers to support robotics, autonomous driving, and satellite network businesses

Elon Musk is accelerating his chip localization strategy, planning to build a complete chip industry chain in the United States, from printed circuit boards (PCB), fan-out panel-level packaging (FOPLP) to wafer manufacturing, in order to gradually reduce dependence on external supply chains.

On November 16, according to media reports, the plan has entered a substantial advancement phase. The new PCB center located in Texas is now operational, and the FOPLP factory has also begun equipment installation, with small-scale mass production expected to be achieved in the third quarter of 2026. According to Wall Street Watch, Musk clearly expressed his intention to "make chips" at Tesla's annual shareholder meeting.

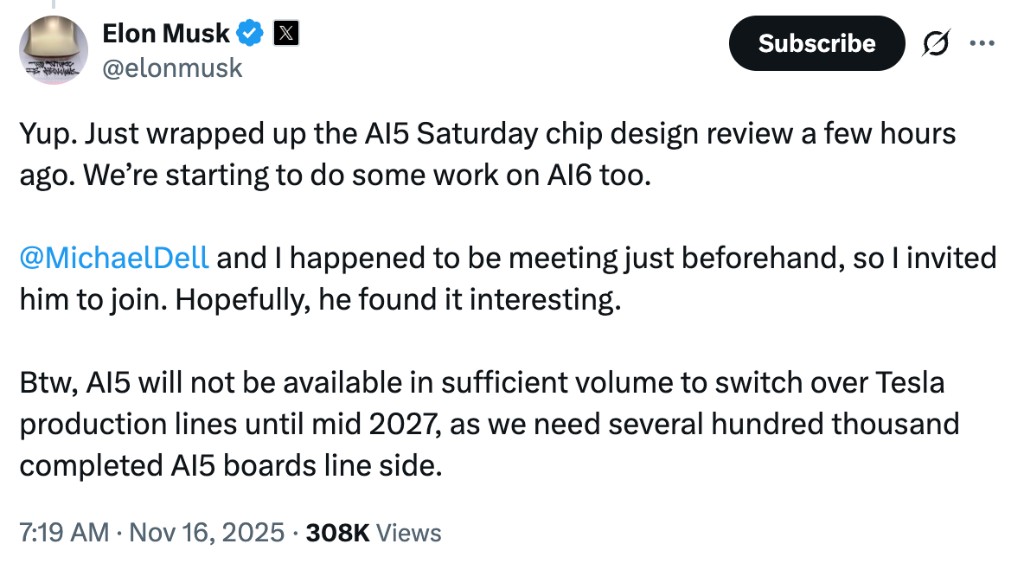

In his latest social media update, Musk revealed that his team completed the design review of the AI5 chip on Saturday and has simultaneously initiated early research and development work on the AI6 chip. He emphasized that the AI5 is a custom inference chip specifically designed for Tesla's AI software, with power consumption reduced to around 250 watts, which is crucial for Optimus. Its performance will comprehensively surpass any other chip solutions on the market in specific application scenarios.

Production Facilities Have Started Deployment

Musk's chip industry chain plan includes two core facilities. The PCB center in Texas has begun operations, providing foundational support for subsequent production. The FOPLP factory is currently in the equipment installation phase, with limited production expected to start in the third quarter of 2026.

SpaceX is the main driving force behind this strategy. The company plans to integrate satellite chip packaging processes to reduce costs and achieve complete control over Starlink components. Before the establishment of autonomous production capacity, the company procured RF and power management chips from STMicroelectronics and Innolux, but these external procurements will gradually decrease after internal capacity is enhanced in 2027.

According to media reports, Musk has recruited technicians from Intel, TSMC, and Samsung, demonstrating his high regard for the chip business.

Wafer Factory Aims for Million-Piece Capacity

To fully achieve chip localization, Musk plans to build a large wafer factory, with an initial monthly production capacity target of 100,000 pieces, ultimately aiming to reach 1 million pieces. Although the factory may struggle to compete with TSMC on advanced process nodes, it will have production capabilities of 14 nanometers and more advanced processes, sufficient to support the needs of robotics, autonomous driving, and satellite networks.

This capacity planning allows Tesla and SpaceX to avoid geopolitical risks and capacity constraints. A stable chip supply is crucial for Tesla's autonomous driving technology and SpaceX's Starlink project Elon Musk previously had disagreements with TSMC regarding capacity prioritization, which became one of the direct motivations for building his own supply chain. By controlling the entire process from design to production, Musk's companies can produce according to their own needs and timelines, without being constrained by external suppliers.

Independent Supply Chain to Address AI Demand Surge

The strategy of establishing an independent supply chain aligns with Musk's goal of addressing the anticipated surge in AI demand. As artificial intelligence applications expand, chip demand is expected to continue rising, and reliance on external suppliers may face delivery bottlenecks during peak demand periods.

Musk's approach essentially involves building a self-sufficient system similar to TSMC and Tokyo Electron, but scaled and positioned specifically to serve his own companies. This vertical integration model provides greater flexibility and security in critical supply chain segments.

Starting in the second half of 2026, Musk's companies will gradually withdraw production orders from partners and shift to in-house manufacturing. This transition will directly impact the order volumes of existing suppliers and also marks an acceleration of the trend toward autonomy in the chip sector among tech giants.

Risk Warning and Disclaimer

The market carries risks, and investment should be approached with caution. This article does not constitute personal investment advice and does not take into account the specific investment objectives, financial situation, or needs of individual users. Users should consider whether any opinions, views, or conclusions in this article are suitable for their specific circumstances. Investing based on this is at one's own risk