The country's first large-capacity all-solid-state battery production line has been completed

The country's first large-capacity all-solid-state battery production line has been completed and is currently undergoing small batch test production. Compared to traditional lithium-ion batteries, all-solid-state batteries have higher energy density and safety. GAC Group has achieved breakthroughs in production processes and electrolyte materials through technological innovation, planning to conduct small batch vehicle loading tests in 2026 and gradually ramp up mass production from 2027 to 2030

All-solid-state batteries are a new important driving force for the future development of the new energy vehicle industry. Recently, reporters learned that the first large-capacity all-solid-state battery production line has been established in China, and it is currently undergoing small-batch testing production.

Compared to traditional lithium-ion batteries, the biggest advantage of all-solid-state batteries is that they contain no liquid at all, but rather solid materials. All-solid-state batteries allow future new energy vehicles to travel further and be safer.

Reporters learned that the advantages of "liquid-free" batteries actually stem from two key innovations in the production line. In the anode manufacturing process, traditional liquid batteries require three independent processes: slurry preparation, coating, and rolling, while the dry process directly combines these three processes into one, reducing energy consumption and improving efficiency.

Senior Manager of GAC Group Solid-State Battery Platform Shi Liurong: The traditional wet process has a surface capacity of less than 5 milliampere-hours per square centimeter, but now it can reach up to 7.7 milliampere-hours per square centimeter; the batteries produced this way have higher energy density, allowing for longer range when installed in vehicles.

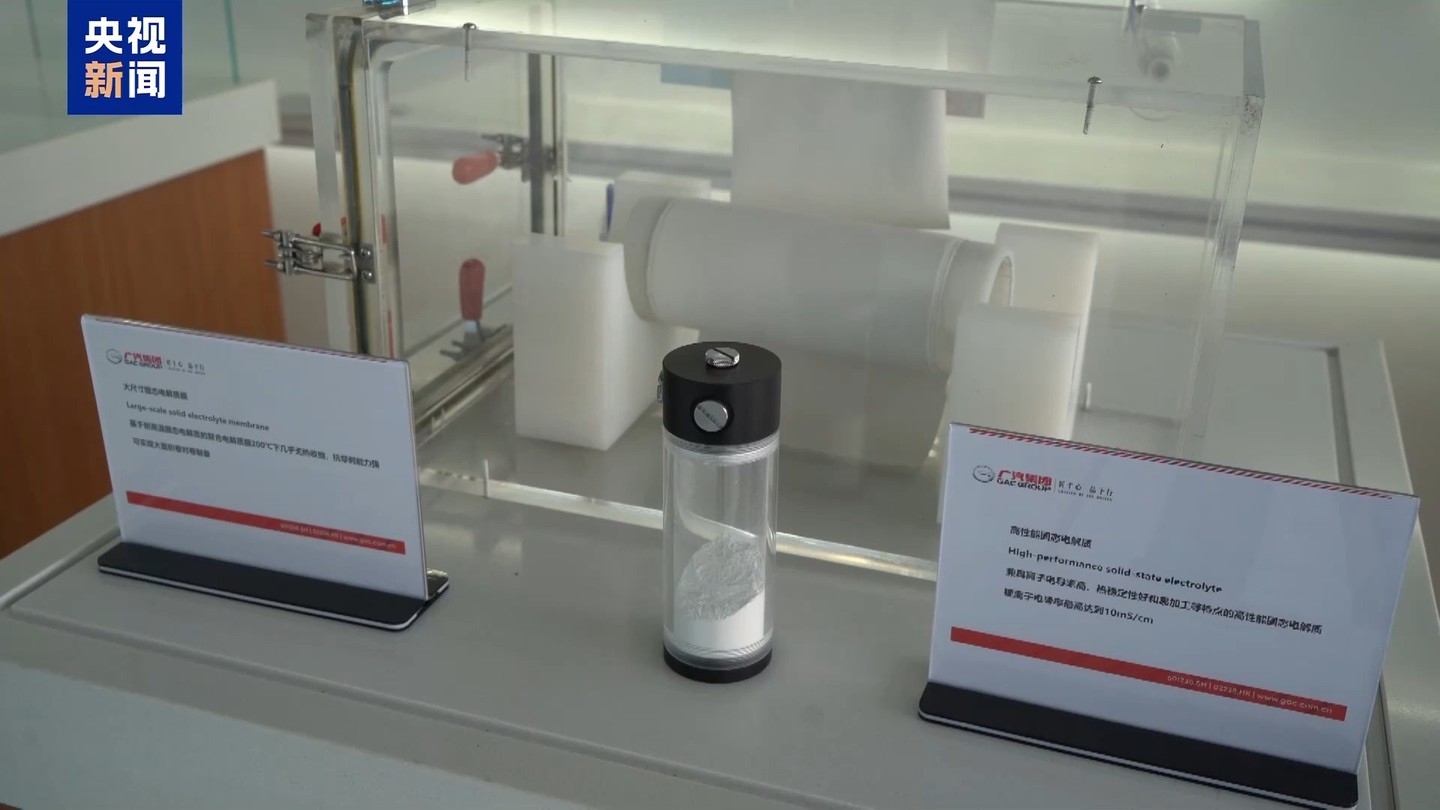

Experts say that in addition to optimizing the production process, another core breakthrough is the change in electrolytes. Here, they have abandoned traditional liquid electrolytes and instead used self-developed solid electrolyte materials, significantly enhancing the product's heat resistance and safety.

Senior Manager of GAC Group Solid-State Battery Platform Shi Liurong: The solid-state electrolyte used in all-solid-state batteries has the significant advantage of good heat resistance, capable of withstanding temperatures above three to four hundred degrees Celsius, while traditional liquid electrolytes can only withstand temperatures of just over one hundred degrees Celsius, less than two hundred degrees Celsius.

With technological breakthroughs in the production line, the next step is to implement industrialization. At GAC Group, the first large-capacity all-solid-state battery production line in China has been established, which is the first in the industry to have the conditions for mass production of automotive-grade all-solid-state batteries with a capacity of over 60 ampere-hours.

GAC Group Platform Technology Research Institute New Energy Power Research and Development Head Qi Hongzhong: The energy density of the all-solid-state batteries currently under development is nearly double that of existing batteries. Vehicles with a range of over 500 kilometers can achieve a range of over 1,000 kilometers after use. The plan is to conduct small-scale vehicle loading experiments in 2026, and from 2027 to 2030, gradually move towards mass production.

GAC Group Platform Technology Research Institute New Energy Power Research and Development Head Qi Hongzhong: The energy density of the all-solid-state batteries currently under development is nearly double that of existing batteries. Vehicles with a range of over 500 kilometers can achieve a range of over 1,000 kilometers after use. The plan is to conduct small-scale vehicle loading experiments in 2026, and from 2027 to 2030, gradually move towards mass production.

Risk Warning and Disclaimer

The market has risks, and investment requires caution. This article does not constitute personal investment advice and does not take into account the specific investment goals, financial situation, or needs of individual users. Users should consider whether any opinions, views, or conclusions in this article align with their specific circumstances. Investment based on this is at one's own risk